-

Stainless Steel Magnetic Drive Pump (49)

-

Mag Drive Turbine Pump (2)

-

High Temperature Magnetic Drive Pump (6)

-

Heating Jacket Magnetic Drive Pump (2)

-

Self Priming Mag Drive Pump (1)

-

Fluoropolymer lined Magnetic Drive Pump (50)

-

Canned Motor Pump (32)

-

Pneumatic Diaphragm Pump (16)

-

Electrical Diaphragm Pump (2)

-

Mechanical Centrifugal Pump (4)

-

Others (0)

| Contacts: | Miss. Susan Meng |

|---|---|

| Email: | susanmeng@ricitepump.com |

| Tel: | +8618217690219 |

| Whatapp: | 8618217690219 |

| Wechat: | +8618217690219 |

High Heat Resistant Canned Motor Pump for Thermal Oil

| Place of Origin: | China |

| Brand Name: | RICITE |

| Model Number: | SH |

| Minimum Order Quantity: | 1 set |

| Packaging Details: | WOODEN CASE |

| Delivery Time: | 5-8 work dayes |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 sets per day |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | RICITE |

|---|---|---|---|

| Model Number | SH | Product Name: | SH Series Ultra-heat-resistant Canned Motor Pumps |

| Color: | Red,blue Customized | Flow: | 300m3/h |

| Lift: | 200m | Temperature: | ~+350℃ |

| Power: | 132kW | Viscosity: | 100mm/s |

| Pressure: | 2.5MPa | Application: | Petroleum, Chemical, Pharmaceutical, Electroplating |

| High Light: | Sealless Canned Pump 300m3/H,132kW Sealless Canned Pump,132kW Sealless Pump |

||

Product Description

SH Series Ultra-heat-resistant Canned Motor Pumps

DESCRIPTION

DESCRIPTION

The super heat-resistant series Canned Motor pump can transport 350°C high-temperature liquids without the need for cooling water, and is a shielded electric pump for high-temperature liquids without heat loss. Super heat-resistant shielded electric pump with inorganic insulation system. In the absence of motor cooling water, it can transport high-temperature liquids with temperatures up to 350C, greatly reducing the heat loss in the system, and can use the heat loss of the motor as a heating source, thus having the characteristics of high efficiency and energy conservation. Due to the use of high-temperature conveyor fluid for cooling, the heat resistance temperature of the motor is the sum of the temperature rise of the conveyor fluid and the motor temperature. After heat resistance life test, it was confirmed that its heat resistance temperature can reach 400°C

SH canned motor pump It adopts international standard design, the maximum operating flow is 1200m3/h, the maximum head is 600m, the temperature range is -120-350°C, and the maximum pressure of the system design is 20MPa.

ADVANTAGES

ADVANTAGES

(1) Long service life, automatic hydraulic thrust balance system combined with silicon carbide bearings to obtain high service life;

(2) High efficiency, optimized motor design and high-efficiency hydraulic research, achieved excellent energy efficiency;

(3) High reliability, advanced processing technology, high-tech CNC equipment and perfect testing to ensure the stability of product performance;

(4) Monitor bearing wear to realize online monitoring and automatic control;

(5) Secondary sealing to ensure the safety to the environmental even in the accident situation.

The super heat-resistant shielded electric pump is most suitable for the following purposes

High temperature liquid pump

For a long time, in order to transport high-temperature liquids, a high-temperature separation type (B-type) electric pump cooled with water has been used. Compared with this type of electric pump, the super heat-resistant shielded electric pump has the following advantages.

1. It can reduce heat loss and convert the loss of the motor into a heating source, thus greatly saving energy. 2. No need for cooling water, reducing operating costs 3. Simple structure, easy to maintain pump for high melting point liquid

High melting point liquid type (K-type) electric pumps have always been used, while maintaining the temperature of the liquid receiving part above the liquid melting point, in order to avoid

The motor coil exceeds the heat-resistant temperature, and after starting operation, it is necessary to switch the jacket from "insulation" to "cooling". Therefore, compared to this type of pump, ultra durable heat pumps have the following advantages

1. After operation, there is no need to switch operations, and the operation is simple

2. Simple structure.

3. No need to use cooling water

other

1. Equipped with a TRG meter, it can monitor the operating status externally and its reliability has been proven.

2. Fully leverage the advantages of shielded electric pumps.

3. Due to its interchangeability with general shielded electric pumps, it can efficiently provide a variety of models

FEATURES

FEATURES

Canned motor pump is composed by canned motor and pump, the inner surface of the stator and the outer surface of the rotor are covered by a thin-walled non-magnetic corrosion-resistant metal, so the stator winding, the rotor core will not be eroded by the conveying liquid, due to they are completely separated. In addition, the impeller is directly installed at the shaft extension of the rotor, the entire rotor is immersed in the conveying liquid, no rotating parts extend outside, is a structure without leakage, so it has the following advantages

(1) Leak free, it is suitable for transporting toxic, explosive, flammable, purified, corrosive liquids;

(2) Complete seal, it is suitable for transporting liquids which is easy to oxidize;

(3) No mechanical seal, it is suitable for conveying high system pressure liquids, high melting point liquids, high temperature liquids, and low temperature liquids.

(4) Using medium as the lubrication, no need grease, no contamination to the transported liquid, no need of grease injection and drainage, either;

(5) Due to the motor and pump are coaxial integration, it is space saving, light in weight, compact design, easy to maintain and dismantle;

(6) The motor adopts water cooling or natural cooling, no fan, so the running vibration is less and the noise is lower.

Precautions when selecting a shielded pump: Generally, shielded pumps use a portion of the liquid conveyed to cool the motor, and the annular gap is very small, so the liquid conveyed must be clean. For conveying various liquid mixtures, if they produce precipitation, coking, or gelatinous substances, selecting a shielded pump (non slurry type) may block the shielding gap, affect the cooling and lubrication of the pump, and cause the graphite bearings and motor to burn out. Shielded pumps generally have circulating cooling pipes. When the ambient temperature is lower than the freezing point of the pumped liquid, it is advisable to use anti freezing measures such as accompanying pipes to ensure convenient pump startup. In addition, when starting the shielded pump, the opening sequence of the outlet and inlet valves should be strictly followed. When stopping the pump, the outlet valve should be turned down first. When the pump stops running, the inlet valve should be closed first and then the outlet valve. In short, the use of shielded pumps is completely leak free, effectively avoiding environmental pollution and material loss. As long as the selection is correct and there are no abnormal changes in operating conditions, there is almost no maintenance workload under normal operation. Shielded pump is an ideal pump for transporting flammable, explosive, corrosive, and precious liquids.

PARAMETERS

PARAMETERS

| NAME | TYPE | FLOW | HEAD | OPERATING TEMPERATURE | POWER | VISICOSITY | PRESSURE | REMARKS |

| SH ultra-heat-resistant canned motor pump | SH ultra-heat-resistant type | 300m3/h | 200m | ~+350℃ | 132kW | 100mm/s | 2.5MPa | Suitable for ultra-heat-resistant medium |

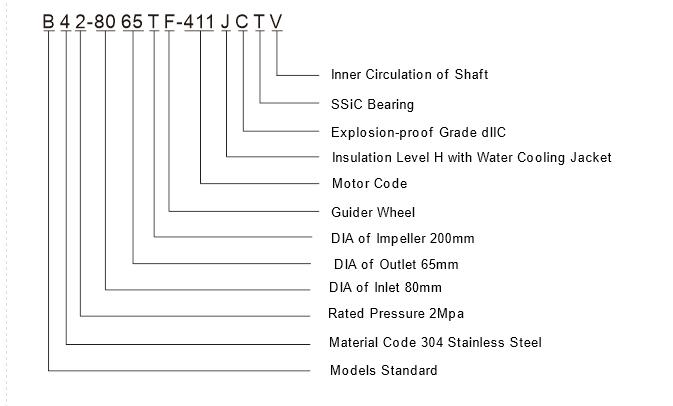

MODEL DESCRIPTION

MODEL DESCRIPTION

MATERIALS

MATERIALS

| CODE | 4 | 5 | 6 | 7 | |

| WETTED PARTS | 304 | 304L | 316 | 316L | |

| Gasket | Pump | High temperature | Graphite winded | ||

| Standard | PTFE | ||||

| Motor | PTFE | ||||

| Can | Hastelloy Alloy -C | Hastelloy Alloy -C | |||

| Shaft | 304/301 | 304L | 316 | 316L | |

| Shaft sleeve, Thrust ring | Stellite | ||||

| SSiC | |||||

| Bearing | Graphite impregnated furan resin, SSiC | ||||

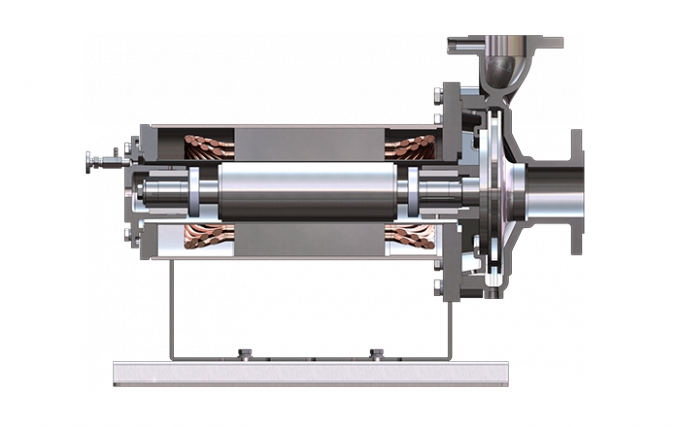

SECTIONAL DRAWING

SECTIONAL DRAWING

MODELS

MODELS

|

No. |

Pump Model |

Speed | Power (KW) | |||

| n=2900r/min | 介质密度(Medium Density(g/cm)) | |||||

| Flow m3/h | Head m | 1 | 1.35 | 1.84 | ||

| 1 | 4025R | 3.6 | 20 | 1.1 | 1.5 | 2.2 |

| 6 | 19 | 1.5 | 2.2 | 2.2 | ||

| 7.2 | 17 | 1.5 | 2.2 | 2.2 | ||

| 2 | 4025S | 7.2 | 33 | 2.2 | 3 | 5.5 |

| 12 | 29 | 3 | 3.7 | 5.5 | ||

| 14.4 | 27 | 3 | 5.5 | 6.3 | ||

| 3 | 4025T | 5.4 | 62 | 5.5 | 6.3 | 7.5 |

| 9 | 60 | 5.5 | 7.5 | 11 | ||

| 10 | 58 | 5.5 | 7.5 | 11 | ||

| 4 | 5040R | 7.2 | 17 | 1.1 | 1.5 | 2.2 |

| 12 | 15 | 1.5 | 2.2 | 3 | ||

| 13.5 | 14.5 | 1.5 | 2.2 | 3 | ||

| 5 | 5040S | 7.2 | 33 | 2.2 | 3 | 5.5 |

| 12 | 29 | 3 | 3.7 | 5.5 | ||

| 14.4 | 27 | 3 | 3.7 | 5.5 | ||

| 6 | 5040T | 10.8 | 52 | 5.5 | 7.5 | 11 |

| 18 | 49 | 6.3 | 11 | 15 | ||

| 21 | 46 | 7.5 | 11 | 15 | ||

| 7 | 5040U | 7.2 | 102 | 15 | 18.5 | 22 |

| 12 | 98 | 15 | 18.5 | 25 | ||

| 14.4 | 94 | 15 | 18.5 | 25 | ||

| 8 | 6550R | 14.4 | 17 | 2.2 | 3 | 5.5 |

| 24 | 14 | 3 | 3.7 | 5.5 | ||

| 28.8 | 12 | 3 | 3.7 | 5.5 | ||

| 9 | 6550S | 14.4 | 30 | 3.7 | 5.5 | 6.3 |

| 24 | 27 | 3.7 | 5.5 | 7.5 | ||

| 28.8 | 24 | 5.5 | 6.3 | 7.5 | ||

| 10 | 6550T | 14.4 | 52 | 7.5 | 11 | 15 |

| 24 | 50 | 11 | 15 | 18.5 | ||

| 28.8 | 46 | 11 | 15 | 18.5 | ||

| 11 | 6550U | 21.6 | 86 | 18.5 | 22 | 30 |

| 36 | 80 | 18.5 | 25 | 37 | ||

| 40 | 78 | 22 | 30 | 37 | ||

|

No. |

Pump Model |

Speed | Power(Kw) | |||

| n=2900r/min | (Medium Density(g/cm3) | |||||

| Flow m3/h | Head m | 1 | 1.35 | 1.84 | ||

| 12 | 8065R | 28.8 | 15 | 3 | 5.5 | 6.3 |

| 48 | 12 | 3.7 | 5.5 | 6.3 | ||

| 55 | 10 | 3.7 | 5.5 | 6.3 | ||

| 13 | 8065S | 36 | 30 | 6.3 | 11 | 15 |

| 60 | 22 | 7.5 | 11 | 15 | ||

| 66 | 18 | 7.5 | 11 | 15 | ||

| 14 | 8065T | 30 | 53 | 11 | 15 | 22 |

| 50 | 50 | 15 | 18.5 | 25 | ||

| 58 | 42 | 15 | 18.5 | 25 | ||

| 15 | 8065U | 28.8 | 80 | 18.5 | 22 | 30 |

| 48 | 76 | 22 | 25 | 37 | ||

| 57.6 | 70 | 22 | 30 | 45 | ||

| 16 | 1080S | 54 | 24 | 11 | 15 | 18.5 |

| 90 | 20 | 11 | 15 | 18.5 | ||

| 102 | 16 | 11 | 15 | 18.5 | ||

| 17 | 1080T | 60 | 50 | 22 | 30 | 37 |

| 100 | 45 | 25 | 30 | 45 | ||

| 120 | 36 | 25 | 30 | 45 | ||

| 18 | 1080U | 60 | 80 | 37 | 45 | 55 |

| 100 | 72 | 45 | 55 | 75 | ||

| 120 | 64 | 45 | 55 | 75 | ||

| 19 | 1080V | 54 | 120 | 55 | 65 | 90 |

| 90 | 100 | 55 | 75 | 110 | ||

| 108 | 80 | 55 | 75 | 110 | ||

| 20 | 1210T | 108 | 45 | 37 | 45 | 55 |

| 180 | 38 | 45 | 45 | 75 | ||

| 200 | 35 | 45 | 45 | 75 | ||

| 21 | 1210U | 108 | 80 | 55 | 65 | 90 |

| 180 | 70 | 65 | 75 | 110 | ||

| 216 | 60 | 65 | 90 | 110 | ||

| 22 | 1210V | 90 | 128 | 75 | 90 | 132 |

| 150 | 120 | 90 | 132 | 200 | ||

| 170 | 110 | 110 | 145 | 200 | ||

More than 10,000+ customers in chemical, pharmaceutical, new energy, electronic aluminum foil and other industries have chosen RICITE products (magnetic drive pumps, chemical canned motor pumps, diaphragm pumps, mechanical seal centrifugal pumps, etc.), and Ricite (Zhejiang) Science & Technology Co., Ltd. has taken part in editing several industry technical standards and specifications, and won the honors of high-tech, energy-saving products and many other patents. Ricite (Zhejiang) Science & Technology Co., Ltd. is committed to manufacturing leak-free pumps, and adheres to the goal of developing magnetic drive pumps, chemical canned motor pumps, and other pumps, and pursues the technological innovation and providing reliable, high cost-efficient and energy-saving pumps and services to customers.

Website: www.ricitepump.com