-

Stainless Steel Magnetic Drive Pump (49)

-

Mag Drive Turbine Pump (2)

-

High Temperature Magnetic Drive Pump (6)

-

Heating Jacket Magnetic Drive Pump (2)

-

Self Priming Mag Drive Pump (1)

-

Fluoropolymer lined Magnetic Drive Pump (50)

-

Canned Motor Pump (32)

-

Pneumatic Diaphragm Pump (16)

-

Electrical Diaphragm Pump (2)

-

Mechanical Centrifugal Pump (4)

-

Others (0)

| Contacts: | Miss. Susan Meng |

|---|---|

| Email: | susanmeng@ricitepump.com |

| Tel: | +8618217690219 |

| Whatapp: | 8618217690219 |

| Wechat: | +8618217690219 |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | RICITE |

|---|---|---|---|

| Model Number | D | Product Name: | D Series Slurry Canned Motor Pump |

| Color: | Red,blue Customized | Flow: | 1000m3/h |

| Lift: | 200m | Temperature: | ~+150℃ |

| Power: | 160kW | Viscosity: | 100mm/s |

| Pressure: | 2.5MPa | Application: | Petroleum, Chemical, Pharmaceutical, Electroplating |

| High Light: | centrifugal slurry pump,Canned Vacuum Pump 1000m3/H,centrifugal pump for slurry |

||

Product Description

D Series Slurry Canned Motor Pump

DESCRIPTION

DESCRIPTION

The DSlurry mud type is suitable for conveying liquids mixed with a large amount of mud.

The drive of an ordinary centrifugal pump is achieved by connecting the impeller shaft of the pump with the electric shaft through a coupling, allowing the impeller to rotate together with the electric motor to work. A cnanned motor pump is an unsealed pump, and both the pump and the driving motor are sealed in a pressure vessel filled with the pumped medium. This pressure vessel is only statically sealed, and a set of wires is used to provide a rotating magnetic field and drive the rotor.

This structure eliminates the rotary shaft sealing device that traditional centrifugal pumps have, making it completely leak free.

The canned motor pump connects the pump and motor together, and the rotor of the motor and the impeller of the pump are fixed on the same shaft. The shielding sleeve is used to separate the rotor and stator of the motor. The rotor operates in the medium being transported, and its power is transmitted to the rotor through the stator magnetic field.

In addition, the manufacturing of canned pumps is not complicated, and their hydraulic end can be designed and manufactured according to the structural types and relevant standards and specifications commonly used in centrifugal pumps.

It adopts international standard design, the maximum operating flow is 1200m3/h, the maximum head is 600m, the temperature range is -120-350°C, and the maximum pressure of the system design is 20MPa.

ADVANTAGES

ADVANTAGES

(1) Long service life, automatic hydraulic thrust balance system combined with silicon carbide bearings to obtain high service life;

(2) High efficiency, optimized motor design and high-efficiency hydraulic research, achieved excellent energy efficiency;

(3) High reliability, advanced processing technology, high-tech CNC equipment and perfect testing to ensure the stability of product performance;

(4) Monitor bearing wear to realize online monitoring and automatic control;

(5) Secondary sealing to ensure the safety to the environmental even in the accident situation.

FEATURES

FEATURES

Characteristics of canned pump:

1. The integrated structure of the motor and pump adopts static sealing, making the electric pump completely leak free.

2. The fully enclosed and leak free structure can transport toxic and harmful liquid substances.

3. The use of a shielded water-cooled motor and the elimination of a cooling fan make the pump operate with low noise and silence, suitable for situations with high environmental noise requirements.

4. The use of graphite sliding bearings lubricated with conveying media reduces operating noise and eliminates the need for manual refueling, reducing maintenance costs. In recent years, bearing materials have also increased, such as silicon carbide (SIC) and superhard, with a service life better than graphite bearings.

5. The vertical structure can be installed on the pipeline like a valve, making installation convenient and fast. During maintenance, only the motor and impeller need to be pulled out without the need to remove the pipeline.

6. It can be installed and operated in conjunction with shock absorbers or shock pads, making the noise of the electric pump lower during operation.

PARAMETERS

PARAMETERS

| NAME | TYPE | FLOW | HEAD | OPERATING TEMPERATURE | POWER | VISICOSITY | PRESSURE | REMARKS |

| D series mud canned motor pump | (D series) | 1000m3/h | 200m | ~+150℃ | 160kW | 100mm/s | 2.5MPa |

Suitable for chemical treatment fluids and catalysts containing small size and low portion particles |

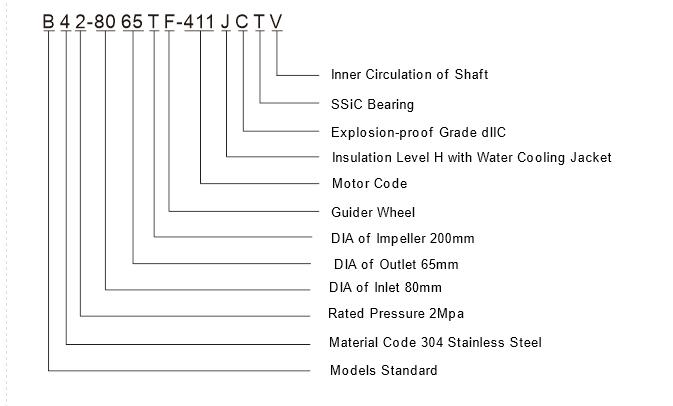

MODEL DESCRIPTION

MODEL DESCRIPTION

MATERIALS

MATERIALS

| CODE | 4 | 5 | 6 | 7 | |

| WETTED PARTS | 304 | 304L | 316 | 316L | |

| Gasket | Pump | High temperature | Graphite winded | ||

| Standard | PTFE | ||||

| Motor | PTFE | ||||

| Can | Hastelloy Alloy -C | Hastelloy Alloy -C | |||

| Shaft | 304/301 | 304L | 316 | 316L | |

| Shaft sleeve, Thrust ring | Stellite | ||||

| SSiC | |||||

| Bearing | Graphite impregnated furan resin, SSiC | ||||

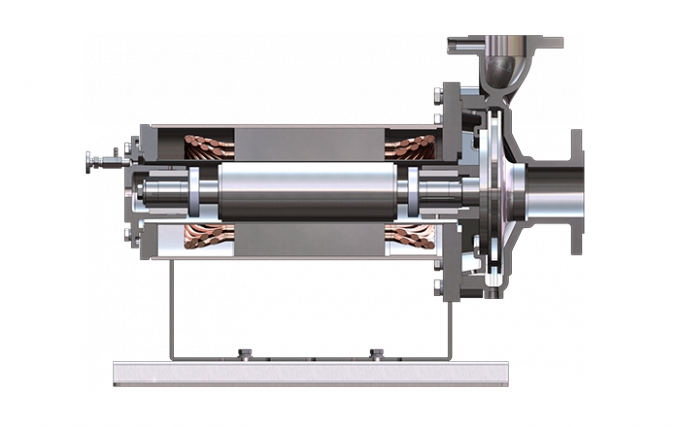

SECTIONAL DRAWING

SECTIONAL DRAWING

MODELS

MODELS

|

No. |

Pump Model |

Speed | Power (KW) | |||

| n=2900r/min | 介质密度(Medium Density(g/cm)) | |||||

| Flow m3/h | Head m | 1 | 1.35 | 1.84 | ||

| 1 | 4025R | 3.6 | 20 | 1.1 | 1.5 | 2.2 |

| 6 | 19 | 1.5 | 2.2 | 2.2 | ||

| 7.2 | 17 | 1.5 | 2.2 | 2.2 | ||

| 2 | 4025S | 7.2 | 33 | 2.2 | 3 | 5.5 |

| 12 | 29 | 3 | 3.7 | 5.5 | ||

| 14.4 | 27 | 3 | 5.5 | 6.3 | ||

| 3 | 4025T | 5.4 | 62 | 5.5 | 6.3 | 7.5 |

| 9 | 60 | 5.5 | 7.5 | 11 | ||

| 10 | 58 | 5.5 | 7.5 | 11 | ||

| 4 | 5040R | 7.2 | 17 | 1.1 | 1.5 | 2.2 |

| 12 | 15 | 1.5 | 2.2 | 3 | ||

| 13.5 | 14.5 | 1.5 | 2.2 | 3 | ||

| 5 | 5040S | 7.2 | 33 | 2.2 | 3 | 5.5 |

| 12 | 29 | 3 | 3.7 | 5.5 | ||

| 14.4 | 27 | 3 | 3.7 | 5.5 | ||

| 6 | 5040T | 10.8 | 52 | 5.5 | 7.5 | 11 |

| 18 | 49 | 6.3 | 11 | 15 | ||

| 21 | 46 | 7.5 | 11 | 15 | ||

| 7 | 5040U | 7.2 | 102 | 15 | 18.5 | 22 |

| 12 | 98 | 15 | 18.5 | 25 | ||

| 14.4 | 94 | 15 | 18.5 | 25 | ||

| 8 | 6550R | 14.4 | 17 | 2.2 | 3 | 5.5 |

| 24 | 14 | 3 | 3.7 | 5.5 | ||

| 28.8 | 12 | 3 | 3.7 | 5.5 | ||

| 9 | 6550S | 14.4 | 30 | 3.7 | 5.5 | 6.3 |

| 24 | 27 | 3.7 | 5.5 | 7.5 | ||

| 28.8 | 24 | 5.5 | 6.3 | 7.5 | ||

| 10 | 6550T | 14.4 | 52 | 7.5 | 11 | 15 |

| 24 | 50 | 11 | 15 | 18.5 | ||

| 28.8 | 46 | 11 | 15 | 18.5 | ||

| 11 | 6550U | 21.6 | 86 | 18.5 | 22 | 30 |

| 36 | 80 | 18.5 | 25 | 37 | ||

| 40 | 78 | 22 | 30 | 37 | ||

|

No. |

Pump Model |

Speed | Power(Kw) | |||

| n=2900r/min | (Medium Density(g/cm3) | |||||

| Flow m3/h | Head m | 1 | 1.35 | 1.84 | ||

| 12 | 8065R | 28.8 | 15 | 3 | 5.5 | 6.3 |

| 48 | 12 | 3.7 | 5.5 | 6.3 | ||

| 55 | 10 | 3.7 | 5.5 | 6.3 | ||

| 13 | 8065S | 36 | 30 | 6.3 | 11 | 15 |

| 60 | 22 | 7.5 | 11 | 15 | ||

| 66 | 18 | 7.5 | 11 | 15 | ||

| 14 | 8065T | 30 | 53 | 11 | 15 | 22 |

| 50 | 50 | 15 | 18.5 | 25 | ||

| 58 | 42 | 15 | 18.5 | 25 | ||

| 15 | 8065U | 28.8 | 80 | 18.5 | 22 | 30 |

| 48 | 76 | 22 | 25 | 37 | ||

| 57.6 | 70 | 22 | 30 | 45 | ||

| 16 | 1080S | 54 | 24 | 11 | 15 | 18.5 |

| 90 | 20 | 11 | 15 | 18.5 | ||

| 102 | 16 | 11 | 15 | 18.5 | ||

| 17 | 1080T | 60 | 50 | 22 | 30 | 37 |

| 100 | 45 | 25 | 30 | 45 | ||

| 120 | 36 | 25 | 30 | 45 | ||

| 18 | 1080U | 60 | 80 | 37 | 45 | 55 |

| 100 | 72 | 45 | 55 | 75 | ||

| 120 | 64 | 45 | 55 | 75 | ||

| 19 | 1080V | 54 | 120 | 55 | 65 | 90 |

| 90 | 100 | 55 | 75 | 110 | ||

| 108 | 80 | 55 | 75 | 110 | ||

| 20 | 1210T | 108 | 45 | 37 | 45 | 55 |

| 180 | 38 | 45 | 45 | 75 | ||

| 200 | 35 | 45 | 45 | 75 | ||

| 21 | 1210U | 108 | 80 | 55 | 65 | 90 |

| 180 | 70 | 65 | 75 | 110 | ||

| 216 | 60 | 65 | 90 | 110 | ||

| 22 | 1210V | 90 | 128 | 75 | 90 | 132 |

| 150 | 120 | 90 | 132 | 200 | ||

| 170 | 110 | 110 | 145 | 200 | ||

More than 10,000+ customers in chemical, pharmaceutical, new energy, electronic aluminum foil and other industries have chosen RICITE products (magnetic drive pumps, chemical canned motor pumps, diaphragm pumps, mechanical seal centrifugal pumps, etc.), and Ricite (Zhejiang) Science & Technology Co., Ltd. has taken part in editing several industry technical standards and specifications, and won the honors of high-tech, energy-saving products and many other patents. Ricite (Zhejiang) Science & Technology Co., Ltd. is committed to manufacturing leak-free pumps, and adheres to the goal of developing magnetic drive pumps, chemical canned motor pumps, and other pumps, and pursues the technological innovation and providing reliable, high cost-efficient and energy-saving pumps and services to customers.

Website: www.ricitepump.com