-

Stainless Steel Magnetic Drive Pump (48)

-

Mag Drive Turbine Pump (2)

-

High Temperature Magnetic Drive Pump (6)

-

Heating Jacket Magnetic Drive Pump (2)

-

Self Priming Mag Drive Pump (1)

-

Fluoropolymer lined Magnetic Drive Pump (49)

-

Canned Motor Pump (32)

-

Pneumatic Diaphragm Pump (16)

-

Electrical Diaphragm Pump (2)

-

Mechanical Centrifugal Pump (4)

-

Others (0)

| Contacts: | Miss. Susan Meng |

|---|---|

| Email: | susanmeng@ricitepump.com |

| Tel: | +8618217690219 |

| Whatapp: | 8618217690219 |

| Wechat: | +8618217690219 |

Corrosion Resistant Magnetic Drive Centrifugal Pump for Cresol

| Place of Origin: | China |

| Brand Name: | RICITE |

| Model Number: | RMD-P |

| Minimum Order Quantity: | 1 set |

| Packaging Details: | WOODEN CASE |

| Delivery Time: | 5-8 work dayes |

| Payment Terms: | T/T, , L/C |

| Supply Ability: | 50 sets per day |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | RICITE |

|---|---|---|---|

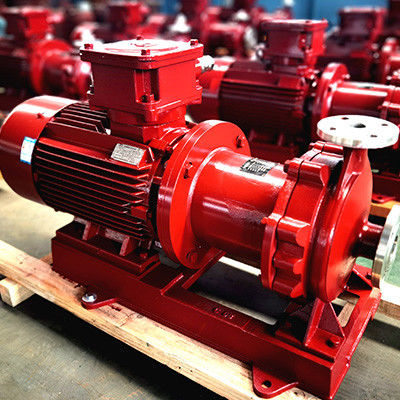

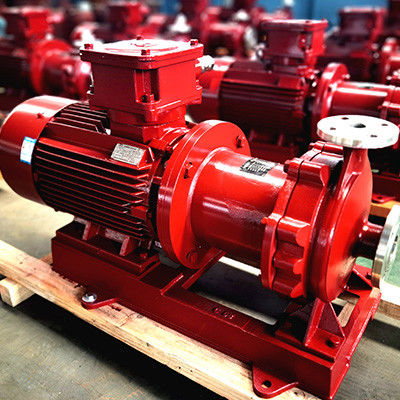

| Model Number | RMD-P | Product Name: | RMD Stainless Steel Magnetic Drive Centrifugal Pump |

| Color: | Red,Blue Customized | Caliber: | 32-300mm |

| Flow: | 3.2-1000m3/h | Lift: | 8-150m |

| Temperature: | -20℃ - +120℃(Customize As Needed+120 ℃ -+350 ℃) | Pressure: | 0-1.6Mpa(Customized 1.6-30Mpa As Needed) |

| Power: | 1.1-315KW | Application: | Petroleum, Chemical, Pharmaceutical, Electroplating |

| Highlight: | Cresol Magnetic Drive Centrifugal Pump,Corrosion Resistant Magnetic Drive Pump |

||

Product Description

RMD stainless steel magnetic pumps

DESCRIPTION

DESCRIPTION

RMD series stainless steel magnetic drive centrifugal pump, the main feature is using magnetic coupling to transmit power, when the motor drives the outer magnetic rotor to rotate, the magnetic field line pass through the gap and the can, acting on the inner magnetic rotor, so that the pump rotors and the motor rotate synchronously, no mechanical contact to transmit torque, in the pump shaft power input section, because the liquid is enclosed in the can, that solves the unavailable defeats of running, falling, dripping, leaking. This type of pump is suitable for the transportation of toxic, harmful, flammable, purified and other corrosive fluids. And it is the ideal pump for creating no leakage, no pollution work environment.

APPLICATION

APPLICATION

RMD series magnetic drive pump is suitable for petroleum, chemical, pharmaceutical, electroplating, food, film and printing, water treatment, national defense, and other industries, is the ideal pump for conveying flammable, explosive, aggressive, toxic, purified, and various corrosive fluids.

The wetted parts of RMD series magnetic drive pump are made of stainless steel, and these pumps are suitable to transport medium with pressure no more than 1.6Mpa, temperature no more than 120℃, and viscosity no more than 30x 10-6 mz V / S, no solid particles and fibers. Please contact sales to get more support if the pressure is more than 1. 6MPa, or the temperature exceeds 120 degrees, or need heat jacket, etc.

FEATURES

FEATURES

1, CFD (Computational Fluid Dynamics) design of hydraulic components, wide flow channel, high efficiency, low NPSHr performance, less radial force.

2. The wetted parts are shaped by precise casting mold, smooth inner wall of the flow channel, and high efficiency.

3. Choose high performance NdFeB (neodymium iron boron) and SmCo (samarium cobalt) permanent magnets to ensure sufficient magnetic torque.

4. Low eddy current can design, so that the efficiency of the pump is higher.

5. Modular parts design, easy to maintain.

6. Plain bearing and shaft adopted high wear resistance, high corrosive-resistance SSiC, unique double bearing positioning structure design, with dynamic lubrication structure, to ensure the stable performance and prolong the service life.

7. Special lubrication and cooling design: the transporting medium is used to take away the heat generated by the eddy current on the can and lubricate the plain bearing, so that the axial force of the pump can automatically balance and ensure the safe running of the pump.

8. The can made of high-quality stainless steel with advanced technology, drain medium completely (when stop to repair) and automatic empty (when to restart).

9. Heat jacket, cooling jacket, or high temperature jacket could to be added if the application required.

PERAMETERS:

PERAMETERS:

| NAME | TYPE | FLOW | HEAD | working temperature | power | speed | DIA OF FLANGE | pressure |

|

Stainless steel magnetic drive pump |

RMD | 3.2-1000m3/h | 8-150m | -20~350℃ | 1.1-315kw | 2900/1450 r/min | 32-200mm | 0-1.6Mpa (1.6-30 Mpa need to be customized) Rotate clockwise from the motor side) |

MODEL CODING:

MODEL CODING:

MODELS:

MODELS:

| Model | Q (m3/h) |

H (m) |

n (r/min) |

η (%) |

Motor | power (Kw) |

| RMD32-20-125 | 3.2 | 20 | 2900 | 16 | YX490S-2 | 1.5 |

| RMD32-20-160 | 3.2 | 32 | 2900 | 18 | YX490L-2 | 2.2 |

| RMD40-25-105 | 6.3 | 12.5 | 2900 | 20 | YX490S-2 | 1.5 |

| RMD40-25-125 | 6.3 | 20 | 2900 | 24 | YX490L-2 | 2.2 |

| RMD40-25-160 | 6.3 | 32 | 2900 | 26 | YX4100L-2 | 3 |

| RMD40-25-200 | 6.3 | 50 | 2900 | 26 | YX4132S1-2 | 5.5 |

| RMD40-25-250 | 6.3 | 80 | 2900 | 20 | YX4160M1-2 | 11 |

| RMD50-32-125 | 12.5 | 20 | 2900 | 34 | YX4100L-2 | 3 |

| RMD50-32-160 | 12.5 | 32 | 2900 | 39 | YX4112M-2 | 4 |

| RMD50-32-200 | 12.5 | 50 | 2900 | 31 | YX4132S2-2 | 7.5 |

| RMD50-32-250 | 12.5 | 80 | 2900 | 25 | YX4160M2-2 | 15 |

| RMD65-50-125 | 25 | 20 | 2900 | 45 | YX4112M-2 | 4 |

| RMD65-50-160 | 25 | 32 | 2900 | 45 | YX4132S2-2 | 7.5 |

| RMD65-40-200 | 25 | 50 | 2900 | 35 | YX4160M2-2 | 15 |

| RMD65-40-250 | 25 | 80 | 2900 | 37 | YX4160L-2 | 18.5 |

| RMD65-40-315 | 25 | 125 | 2900 | 27 | YX4200L2-2 | 37 |

| RMD80-65-125 | 50 | 20 | 2900 | 55 | YX4132S2-2 | 7.5 |

| RMD80-65-160 | 50 | 32 | 2900 | 55 | YX4160M1-2 | 11 |

| RMD80-50-200 | 50 | 50 | 2900 | 50 | YX4160L-2 | 18.5 |

| RMD80-50-250 | 50 | 80 | 2900 | 45 | YX4200L1-2 | 30 |

| RMD80-50-315 | 50 | 125 | 2900 | 40 | YX4250M-2 | 55 |

| RMD100-80-125 | 100 | 20 | 2900 | 61 | YX4160M1-2 | 11 |

| RMD100-80-160 | 100 | 32 | 2900 | 61 | YX4160L-2 | 18.5 |

| RMD100-65-200 | 100 | 50 | 2900 | 60 | YX4200L1-2 | 30 |

| RMD100-65-250 | 100 | 80 | 2900 | 56 | YX4250M-2 | 55 |

| RMD100-65-315 | 100 | 125 | 2900 | 50 | YX4280M-2 | 90 |

More than 10,000+ customers in chemical, pharmaceutical, new energy, electronic aluminum foil and other industries have chosen RICITE products (magnetic drive pumps, chemical canned motor pumps, diaphragm pumps, mechanical seal centrifugal pumps, etc.), and Ricite (Zhejiang) Science & Technology Co., Ltd. has taken part in editing several industry technical standards and specifications, and won the honors of high-tech, energy-saving products and many other patents. Ricite (Zhejiang) Science & Technology Co., Ltd. is committed to manufacturing leak-free pumps, and adheres to the goal of developing magnetic drive pumps, chemical canned motor pumps, and other pumps, and pursues the technological innovation and providing reliable, high cost-efficient and energy-saving pumps and services to customers.

Website: www.ricitepump.com