-

Stainless Steel Magnetic Drive Pump (48)

-

Mag Drive Turbine Pump (2)

-

High Temperature Magnetic Drive Pump (6)

-

Heating Jacket Magnetic Drive Pump (2)

-

Self Priming Mag Drive Pump (1)

-

Fluoropolymer lined Magnetic Drive Pump (49)

-

Canned Motor Pump (32)

-

Pneumatic Diaphragm Pump (16)

-

Electrical Diaphragm Pump (2)

-

Mechanical Centrifugal Pump (4)

-

Others (0)

| Contacts: | Miss. Susan Meng |

|---|---|

| Email: | susanmeng@ricitepump.com |

| Tel: | +8618217690219 |

| Whatapp: | 8618217690219 |

| Wechat: | +8618217690219 |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | RICITE |

|---|---|---|---|

| Model Number | X | Product Name: | X Series Mud Canned Motor Pumps |

| Color: | Red,blue Customized | Flow: | 300m3/h |

| Lift: | 200m | Temperature: | ~+350℃ |

| Power: | 132kW | Viscosity: | 100mm/s |

| Pressure: | 10MPa | Application: | Petroleum, Chemical, Pharmaceutical, Electroplating |

| Highlight: | canned vertical turbine pump,vertical turbine can pump,vertical can pump |

||

Product Description

X series mud canned motor pumps

DESCRIPTION

DESCRIPTION

X series mud canned motor pumps is suitable for conveying liquids mixed with a large amount of mud.

The chemical Canned Motor Pump is composed of a shielding motor and a pump as a whole, with the inner surface of the stator and the outer surface of the rotor covered by a thin-walled non-magnetic corrosion-resistant metal thin cylinder. The stator winding and rotor core are completely separated from the conveying medium and will not be corroded by the conveying liquid. In addition, the impeller is directly installed at the shaft extension end of the rotor, and the entire rotor body is immersed in the conveying liquid without any rotating parts that are connected to the outside world. It is an absolutely leak free structure.

it adopts international standard design, the maximum operating flow is 1200m3/h, the maximum head is 600m, the temperature range is -120-350°C, and the maximum pressure of the system design is 20MPa.

ADVANTAGES

ADVANTAGES

(1) Long service life, automatic hydraulic thrust balance system combined with silicon carbide bearings to obtain high service life;

(2) High efficiency, optimized motor design and high-efficiency hydraulic research, achieved excellent energy efficiency;

(3) High reliability, advanced processing technology, high-tech CNC equipment and perfect testing to ensure the stability of product performance;

(4) Monitor bearing wear to realize online monitoring and automatic control;

(5) Secondary sealing to ensure the safety to the environmental even in the accident situation.

Common faults and maintenance of canned pumps

Common faults and maintenance of canned pumps

1. Canned motor pump cannot pump medium: There is a problem with the suction pipeline, such as blockage or air leakage. Whether the suction or output pipeline valves are closed and whether the management configuration is correct.

Solution: Users can solve the above problems by closing, cleaning, and configuring correctly. There is another situation where theCanned MotorPump cannot extract the medium, which is that the suction pressure head is too low. The corresponding problem can be solved by increasing the suction pressure head.

2. Canned motor pump flow rate too small or too large: There are many reasons for this type of malfunction, which may be blockage or scaling of pipelines, filters, or impellers.

Solution: Just remove the scale and blockages. If the pump is not fully filled with liquid or the inlet valve is not fully opened, simply perform the corresponding operation. If the flow rate is too high, then all you need to do is turn down the outlet valve. Also, if the head of the canned pump is too small, it is a system problem and you need to contact the manufacturer of the canned pump to help resolve it.

3. When the Canned MotorPump is working, the noise is relatively loud or unstable: then it is necessary to consider whether the parts inside the pump, such as bearings, are worn, and whether there are foreign objects inside the Canned motor pump

Solution: If such a situation occurs, it is necessary to contact the manufacturer or professional maintenance personnel for disassembly and repair.

4. The resistance value of the motor winding coil is normal, but the pump cannot rotate: the reason is dry grinding caused by running without liquid, and the rotor shaft sleeve and graphite bearing are stuck. Or due to other mechanical faults causing jamming.

Solution: Disassemble the Canned MotorPump, clean the accessories, and find the fault point. Repair or replace accessories.

5. The motor is fine, but the operating current is too high: the reason is that there is not enough liquid to be conveyed. There is a dry grinding situation. Or there may be mechanical jamming and deviation in the fastening of the motor end cover.

Solution: After decomposition. Clean and reassemble.

FEATURES

FEATURES

Canned motor pump is composed by canned motor and pump, the inner surface of the stator and the outer surface of the rotor are covered by a thin-walled non-magnetic corrosion-resistant metal, so the stator winding, the rotor core will not be eroded by the conveying liquid, due to they are completely separated. In addition, the impeller is directly installed at the shaft extension of the rotor, the entire rotor is immersed in the conveying liquid, no rotating parts extend outside, is a structure without leakage, so it has the following advantages

(1) Leak free, it is suitable for transporting toxic, explosive, flammable, purified, corrosive liquids;

(2) Complete seal, it is suitable for transporting liquids which is easy to oxidize;

(3) No mechanical seal, it is suitable for conveying high system pressure liquids, high melting point liquids, high temperature liquids, and low temperature liquids.

(4) Using medium as the lubrication, no need grease, no contamination to the transported liquid, no need of grease injection and drainage, either;

(5) Due to the motor and pump are coaxial integration, it is space saving, light in weight, compact design, easy to maintain and dismantle;

(6) The motor adopts water cooling or natural cooling, no fan, so the running vibration is less and the noise is lower.

PARAMETERS

PARAMETERS

| NAME | TYPE | FLOW | HEAD | OPERATING TEMPERATURE | POWER | VISICOSITY | PRESSURE | REMARKS |

| X Mud canned motor pump | X mud | 300m3/h | 200m | ~+350℃ | 132kW | 100mm/s | 10MPa |

Suitable for liquids with high proportion of slurry content, such as mud, sewage, crystallization, etc. |

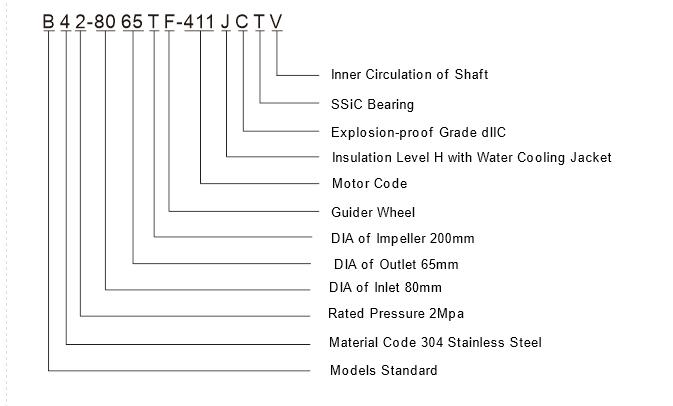

MODEL DESCRIPTION

MODEL DESCRIPTION

MATERIALS

MATERIALS

| CODE | 4 | 5 | 6 | 7 | |

| WETTED PARTS | 304 | 304L | 316 | 316L | |

| Gasket | Pump | High temperature | Graphite winded | ||

| Standard | PTFE | ||||

| Motor | PTFE | ||||

| Can | Hastelloy Alloy -C | Hastelloy Alloy -C | |||

| Shaft | 304/301 | 304L | 316 | 316L | |

| Shaft sleeve, Thrust ring | Stellite | ||||

| SSiC | |||||

| Bearing | Graphite impregnated furan resin, SSiC | ||||

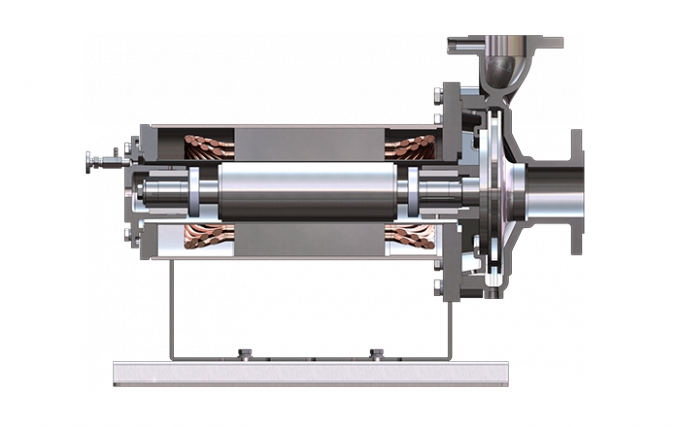

SECTIONAL DRAWING

SECTIONAL DRAWING

MODELS

MODELS

|

No. |

Pump Model |

Speed | Power (KW) | |||

| n=2900r/min | 介质密度(Medium Density(g/cm)) | |||||

| Flow m3/h | Head m | 1 | 1.35 | 1.84 | ||

| 1 | 4025R | 3.6 | 20 | 1.1 | 1.5 | 2.2 |

| 6 | 19 | 1.5 | 2.2 | 2.2 | ||

| 7.2 | 17 | 1.5 | 2.2 | 2.2 | ||

| 2 | 4025S | 7.2 | 33 | 2.2 | 3 | 5.5 |

| 12 | 29 | 3 | 3.7 | 5.5 | ||

| 14.4 | 27 | 3 | 5.5 | 6.3 | ||

| 3 | 4025T | 5.4 | 62 | 5.5 | 6.3 | 7.5 |

| 9 | 60 | 5.5 | 7.5 | 11 | ||

| 10 | 58 | 5.5 | 7.5 | 11 | ||

| 4 | 5040R | 7.2 | 17 | 1.1 | 1.5 | 2.2 |

| 12 | 15 | 1.5 | 2.2 | 3 | ||

| 13.5 | 14.5 | 1.5 | 2.2 | 3 | ||

| 5 | 5040S | 7.2 | 33 | 2.2 | 3 | 5.5 |

| 12 | 29 | 3 | 3.7 | 5.5 | ||

| 14.4 | 27 | 3 | 3.7 | 5.5 | ||

| 6 | 5040T | 10.8 | 52 | 5.5 | 7.5 | 11 |

| 18 | 49 | 6.3 | 11 | 15 | ||

| 21 | 46 | 7.5 | 11 | 15 | ||

| 7 | 5040U | 7.2 | 102 | 15 | 18.5 | 22 |

| 12 | 98 | 15 | 18.5 | 25 | ||

| 14.4 | 94 | 15 | 18.5 | 25 | ||

| 8 | 6550R | 14.4 | 17 | 2.2 | 3 | 5.5 |

| 24 | 14 | 3 | 3.7 | 5.5 | ||

| 28.8 | 12 | 3 | 3.7 | 5.5 | ||

| 9 | 6550S | 14.4 | 30 | 3.7 | 5.5 | 6.3 |

| 24 | 27 | 3.7 | 5.5 | 7.5 | ||

| 28.8 | 24 | 5.5 | 6.3 | 7.5 | ||

| 10 | 6550T | 14.4 | 52 | 7.5 | 11 | 15 |

| 24 | 50 | 11 | 15 | 18.5 | ||

| 28.8 | 46 | 11 | 15 | 18.5 | ||

| 11 | 6550U | 21.6 | 86 | 18.5 | 22 | 30 |

| 36 | 80 | 18.5 | 25 | 37 | ||

| 40 | 78 | 22 | 30 | 37 | ||

|

No. |

Pump Model |

Speed | Power(Kw) | |||

| n=2900r/min | (Medium Density(g/cm3) | |||||

| Flow m3/h | Head m | 1 | 1.35 | 1.84 | ||

| 12 | 8065R | 28.8 | 15 | 3 | 5.5 | 6.3 |

| 48 | 12 | 3.7 | 5.5 | 6.3 | ||

| 55 | 10 | 3.7 | 5.5 | 6.3 | ||

| 13 | 8065S | 36 | 30 | 6.3 | 11 | 15 |

| 60 | 22 | 7.5 | 11 | 15 | ||

| 66 | 18 | 7.5 | 11 | 15 | ||

| 14 | 8065T | 30 | 53 | 11 | 15 | 22 |

| 50 | 50 | 15 | 18.5 | 25 | ||

| 58 | 42 | 15 | 18.5 | 25 | ||

| 15 | 8065U | 28.8 | 80 | 18.5 | 22 | 30 |

| 48 | 76 | 22 | 25 | 37 | ||

| 57.6 | 70 | 22 | 30 | 45 | ||

| 16 | 1080S | 54 | 24 | 11 | 15 | 18.5 |

| 90 | 20 | 11 | 15 | 18.5 | ||

| 102 | 16 | 11 | 15 | 18.5 | ||

| 17 | 1080T | 60 | 50 | 22 | 30 | 37 |

| 100 | 45 | 25 | 30 | 45 | ||

| 120 | 36 | 25 | 30 | 45 | ||

| 18 | 1080U | 60 | 80 | 37 | 45 | 55 |

| 100 | 72 | 45 | 55 | 75 | ||

| 120 | 64 | 45 | 55 | 75 | ||

| 19 | 1080V | 54 | 120 | 55 | 65 | 90 |

| 90 | 100 | 55 | 75 | 110 | ||

| 108 | 80 | 55 | 75 | 110 | ||

| 20 | 1210T | 108 | 45 | 37 | 45 | 55 |

| 180 | 38 | 45 | 45 | 75 | ||

| 200 | 35 | 45 | 45 | 75 | ||

| 21 | 1210U | 108 | 80 | 55 | 65 | 90 |

| 180 | 70 | 65 | 75 | 110 | ||

| 216 | 60 | 65 | 90 | 110 | ||

| 22 | 1210V | 90 | 128 | 75 | 90 | 132 |

| 150 | 120 | 90 | 132 | 200 | ||

| 170 | 110 | 110 | 145 | 200 | ||

More than 10,000+ customers in chemical, pharmaceutical, new energy, electronic aluminum foil and other industries have chosen RICITE products (magnetic drive pumps, chemical canned motor pumps, diaphragm pumps, mechanical seal centrifugal pumps, etc.), and Ricite (Zhejiang) Science & Technology Co., Ltd. has taken part in editing several industry technical standards and specifications, and won the honors of high-tech, energy-saving products and many other patents. Ricite (Zhejiang) Science & Technology Co., Ltd. is committed to manufacturing leak-free pumps, and adheres to the goal of developing magnetic drive pumps, chemical canned motor pumps, and other pumps, and pursues the technological innovation and providing reliable, high cost-efficient and energy-saving pumps and services to customers.

Website: www.ricitepump.com