-

Stainless Steel Magnetic Drive Pump (48)

-

Mag Drive Turbine Pump (2)

-

High Temperature Magnetic Drive Pump (6)

-

Heating Jacket Magnetic Drive Pump (2)

-

Self Priming Mag Drive Pump (1)

-

Fluoropolymer lined Magnetic Drive Pump (49)

-

Canned Motor Pump (32)

-

Pneumatic Diaphragm Pump (16)

-

Electrical Diaphragm Pump (2)

-

Mechanical Centrifugal Pump (4)

-

Others (0)

| Contacts: | Miss. Susan Meng |

|---|---|

| Email: | susanmeng@ricitepump.com |

| Tel: | +8618217690219 |

| Whatapp: | 8618217690219 |

| Wechat: | +8618217690219 |

Coupled Magnetic Drive Centrifugal Pump for Large Flow Application

| Place of Origin: | China |

| Brand Name: | RICITE |

| Model Number: | IHF |

| Minimum Order Quantity: | 1 set |

| Packaging Details: | WOODEN CASE |

| Delivery Time: | 5-8 work dayes |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 sets per day |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | RICITE |

|---|---|---|---|

| Model Number | IHF | Product Name: | IHF Fluoropolymer-lined Mechanical Centrifugal Pump |

| Color: | Red,Blue Customized | Material: | CS+F46 |

| Flow: | 3-400m3/h | Lift: | 15-125m |

| Temperature: | -20℃ - +150℃(Customize As Needed+120 ℃ -+350 ℃) | Pressure: | 1.6MPa(Customized 1.6-30Mpa As Needed) |

| Application: | Petroleum, Chemical, Pharmaceutical, Electroplating | Highlight: | Fluoropolymer lined Mechanical centrifugal pum,Mechanical centrifugal pump for sulphuric acid,centrifugal mud pump |

Product Description

IHF FLUOROPOLYMER-LINED CHEMICAL CENTRIFUGAL PUMPS

DESCRIPTION

DESCRIPTION

IHF series are single-stage single-suction fluoropolymer-lined chemical centrifugal pumps. The pump casing is made of ductile cast iron shell lined with FEP (F46), the casing cover, impeller and shaft sleeve are all made of fluoropolymer with metal core using cold pressing sintering molding, and the inlet and outlet are reinforced with cast iron shell. The shaft seal adopts the current high technical of the external type PTFE corrugated pipe mechanical seal, with multi-layer of protection, prolonging the service life of the seal. For the transportation of solid-laden medium, can be equipped without cooling water two single-ends (silicon carbide to silicon carbide) mechanical seal, so customers need to consider the solid content in the medium when choosing models.

FEATURES

FEATURES

1. IHF series centrifugal pump is designed according to international standards, and the pump casing is metal shell lined with FEP (F46);

2. The casing cover, impeller and shaft sleeve are all made of FEP with metal core using cold pressing sintering molding, and the shaft seal adopts external Corrugated pipe mechanical seal;

3. The stator is made of 99.9% alumina ceramic or silicon nitride;

4. The rotor adopts PTFE filler. It is corrosion resistant, wear-resistant, and good seal performance.

5. The superiors are advanced technology, reasonable structure, strong corrosion resistance, tight and reliable sealing performance, stable work performance, and long service life.

APPLICATIONS

APPLICATIONS

It is suitable for transporting any concentration of sulfuric acid, hydrochloric acid, acetic acid, hydrofluoric acid, nitric acid, aqua regia, strong alkali, strong oxidant, organic solvent, reducing agent and other highly corrosive media under harsh conditions.

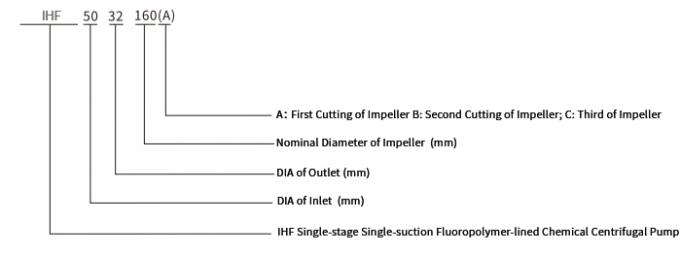

Model Coding

Model Coding

PARAMETERS

PARAMETERS

| NAME | TYPE | FLOW | HEAD | OPERATING TEMPERATURE | POWER OF MOTOR | SPEED | DIA OF FLANGE | OPERATING PRESSURE |

| IHF | IHF | 3-400m3/h | 15-125m | -20~150℃ | 0.75~110kw | 2900/1450 r/min | 32~200mm | 1.6Mpa |

MODELS

MODELS

| MODEL | SPEED=2900r/min | DENSITY1000kg/m3 | SPEED=1450r/min | DENSITY=1000kg/m3 | |||||||

| FLOW (m3/h) | HEAD (m) | POWER (kw) | NPSH (m) | EFFICIENCY (%) | FLOW (m3/h) | HEAD (m) | POWER (kw) | NPSH(m) | EFFICIENCY (%) | ||

| IHF32-25-125 | 2.0 3.2 4.0 |

20.6 20 18 |

1.1 | 2.0 | 37 | ||||||

| IHF32-25-160 | 2.0 3.2 4.0 |

33 32 30 |

1.5 | 2.0 | 35 | ||||||

| IHF40-25-125 | 4 6 8 |

23 20 18.5 |

1.5 | 2.0 | 40 | 2 3 4 |

5.5 5 4.5 |

0.55 | 2.0 | 34 | |

| IHF40-25-160 | 4 6 8 |

34 32 28 |

2.2 | 2.0 | 33 | 2 3 4 |

9 8 7 |

0.55 | 2.0 | 27 | |

| IHF40-25-200 | 4 6 8 |

52 50 48 |

4 | 2.0 | 26 | 2 3 4 |

13.5 12.5 12 |

0.75 | 2.0 | 20 | |

| IHF50-32-125 | 10 12.5 15 |

23 20 18.5 |

2.2 | 3.0 | 51 | 5 6.3 8 |

5.5 5 4.5 |

0.55 | 3.0 | 45 | |

| IHF50-32-160 | 10 12.5 15 |

34 32 28 |

4 | 3.0 | 46 | 5 6.3 8 |

9 8 7 |

0.55 | 3.0 | 40 | |

| IHF50-32-200 | 10 12.5 15 |

52 50 48 |

7.5 | 3.0 | 39 | 5 6.3 8 |

13.5 12.5 12 |

1.1 | 3.0 | 33 | |

| IHF50-32-250 | 10 12.5 15 |

82 80 78 |

11 | 3.5 | 38 | 5 6.3 8 |

20.5 20 19.5 |

1.5 | 3.5 | 32 | |

| IHF65-50-125 | 15 25 30 |

23 20 18.5 |

3 | 3.5 | 62 | 7.5 12.5 15 |

5.5 5 4.5 |

0.55 | 3.5 | 55 | |

| IHF65-50-160 | 15 25 30 |

34 32 28 |

5.5 | 3.5 | 57 | 7.5 12.5 15 |

9 8 7 |

1.1 | 3.5 | 51 | |

| IHF65-40-200 | 15 25 30 |

52 50 48 |

11 | 3.5 | 52 | 7.5 12.5 15 |

13.5 12.5 12 |

1.5 | 3.5 | 46 | |

| IHF65-40-250 | 15 25 30 |

82 80 78 |

18.5 | 3.5 | 50 | 7.5 12.5 15 |

20.5 20 19.5 |

3 | 3.5 | 43 | |

| IHF80-65-125 | 40 50 60 |

23 20 18.5 |

5.5 | 4.0 | 69 | 15 25 30 |

5.5 5 4.5 |

1.1 | 4.0 | 64 | |

| IHF80-65-160 | 40 50 60 |

34 32 28 |

11 | 4.0 | 67 | 15 25 30 |

9 8 7 |

1.5 | 4.0 | 62 | |

| MODEL | SPEED=2900r/min | DENSITY=1000kg/m3 | SPEED=1450r/min | DENSITY=1000kg/m3 | |||||||

| FLOW (m3/h) | HEAD (m) | POWER (kw) | NPSH (m) | EFFICIENCY (%) | FLOW (m3/h) | HEAD (m) | POWER (kw) | NPSH (m) | EFFICIENCY (%) | ||

| IHF80-50-200 | 40 50 60 |

52 50 48 |

15 | 4.0 | 63 | 15 25 30 |

13.5 12.5 12 |

2.2 | 4.0 | 57 | |

| IHF80-50-250 | 40 50 60 |

82 80 78 |

30 | 4.0 | 56 | 15 25 30 |

20.5 20 19.5 |

5.5 | 4.0 | 51 | |

| IHF100-80-125 | 80 100 120 |

22 20 18.5 |

11 | 4.5 | 77 | 40 50 60 |

5.5 5 4.5 |

1.5 | 4.5 | 74 | |

| IHF100-80-160 | 80 100 120 |

34 32 28 |

15 | 4.5 | 73 | 40 50 60 |

9 8 7 |

2.2 | 4.5 | 69 | |

| IHF100-65-200 | 80 100 120 |

52 50 48 |

30 | 4.5 | 73 | 40 50 60 |

13.5 12.5 12 |

5.5 | 4.5 | 68 | |

| IHF100-65-250 | 80 100 120 |

82 80 78 |

45 | 4.5 | 71 | 40 50 60 |

20.5 20 19.5 |

7.5 | 4.5 | 64 | |

| IHF125-100-160 | 120 160 180 |

34 32 28 |

30 | 5.0 | 70 | 80 100 120 |

9 8 7 |

5.5 | 5.0 | 70 | |

| IHF125-100-200 | 240 200 150 |

52 50 48 |

55 | 5.0 | 65 | 80 100 120 |

13.5 12.5 12 |

11 | 5.0 | 71 | |

| IHF150-125-250 | 240 200 150 |

20.5 20 19.5 |

22 | 6.0 | 11 | ||||||

| IHF150-125-315 | 240 200 150 |

34 32 30 |

45 | 6.0 | 75 | ||||||

| IHF150-125-400 | 240 200 150 |

52 50 48 |

55 | 6.0 | 78 | ||||||

| IHF200-150-250 | 250 400 480 |

20.5 20 19.5 |

45 | 7.0 | 74 | ||||||

| IHF200-150-315 | 250 400 480 |

34 32 30 |

75 | 7.0 | 79 | ||||||

| IHF200-150-400 | 250 400 480 |

52 50 48 |

90 | 7.0 | 78 | ||||||

More than 10,000+ customers in chemical, pharmaceutical, new energy, electronic aluminum foil and other industries have chosen RICITE products (magnetic drive pumps, chemical canned motor pumps, diaphragm pumps, mechanical seal centrifugal pumps, etc.), and Ricite (Zhejiang) Science & Technology Co., Ltd. has taken part in editing several industry technical standards and specifications, and won the honors of high-tech, energy-saving products and many other patents. Ricite (Zhejiang) Science & Technology Co., Ltd. is committed to manufacturing leak-free pumps, and adheres to the goal of developing magnetic drive pumps, chemical canned motor pumps, and other pumps, and pursues the technological innovation and providing reliable, high cost-efficient and energy-saving pumps and services to customers.

Website: www.ricitepump.com